- HOME

- Topics

- News Release

- 2022

August 1, 2022

New Production Equipment for Semiconductor-Related Tape Due to Rising Demand for Semiconductors and the Move to Making Thinner, Multilayered Tapes

In response to the recent rapid growth in semiconductor demand, aggressive investment by semiconductor manufacturers to increase production capacity, and dramatic technological innovation, LINTEC has decided to invest approximately 4.5 billion yen in the Agatsuma Plant (Gunma Prefecture). The investment will cover the installation of new state-of-the-art production equipment for related tapes essential to the semiconductor manufacturing process and mounting in order to increase production capacity and further raise product quality.

Increased Production of Specialty Adhesive Tape Essential for Semiconductor Manufacturing that Utilizes Proprietary Technology

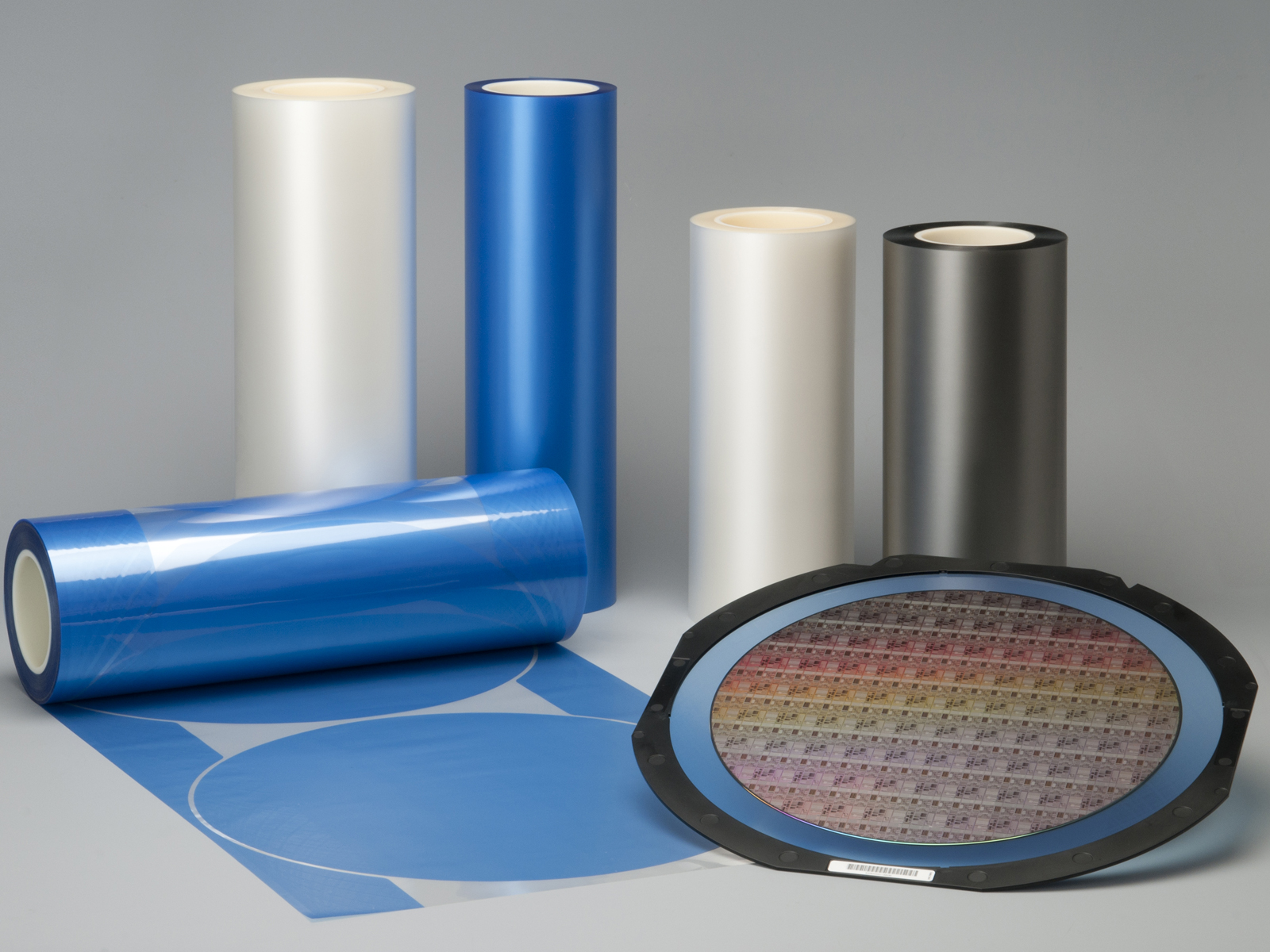

LINTEC develops and provides a variety of specialty adhesive tapes that are essential to the semiconductor manufacturing process and mounting. These include wafer surface protective tape, which protects the circuit surface during the backside grinding process that makes semiconductor wafers thinner after the circuit is formed; wafer backside affixing and chip mounting tape, which is used to firmly secure the wafer when it is cut into chips and as an adhesive when chips are mounted on substrates; and backside coating tape for flip chip packaging, which is used to invert (flip) the chips and mount them.

Recently, semiconductor demand has been increasing rapidly thanks to demand for smartphones, electric vehicles (EVs), and 5G high-speed communications, which has resulted in tight supply and demand. Semiconductor manufacturers are aggressively investing in increased production capacity, so we have decided to invest in increasing new production capacity to enhance our system for the stable supply of higher quality products with the aim of further market growth.

Semiconductor-related tape

State-of-the-Art Production Facilities to Address the Further Increase in Semiconductor Demand and Technological Innovation

The Group will invest approximately 4.5 billion yen in the Agatsuma Plant, the Group's core production base for semiconductor-related products, which is scheduled for completion in December 2023. The investment will cover the installation of one new state-of-the-art clean coater, two cutting equipment, an automated rack building, and other equipment. We will improve the thickness accuracy of wafer surface protective tape and other products, further enhance the quality assurance system to meet automotive standards and create a system to ensure a stable supply of a wide range of tapes.

We will continue to enhance our system so that we can aggressively develop new products for electronics-related markets and continue to provide a stable supply of high-quality products to match the increased investment in production capacity and technological innovation of semiconductor manufacturers.

Existing facility at the Agatsuma Plant where the new equipment will be installed

The contents of the News Release are as of the announcement date. Please note that they may differ from the latest information.