- HOME

- Topics

- News Release

- 2025

August 28, 2025

LINTEC Introduces New Coating Equipment

Boosting Production to Meet Synthetic Leather Demand

LINTEC announced today that it has constructed a new building at its Komatsushima Plant (in Tokushima Prefecture) and installed new coating equipment for casting papers for synthetic leather and other applications, an investment of approximately 4.8 billion yen. The new equipment will begin operating in September 2025.

Improving Production Capacity and Competitiveness Amid Growing Demand

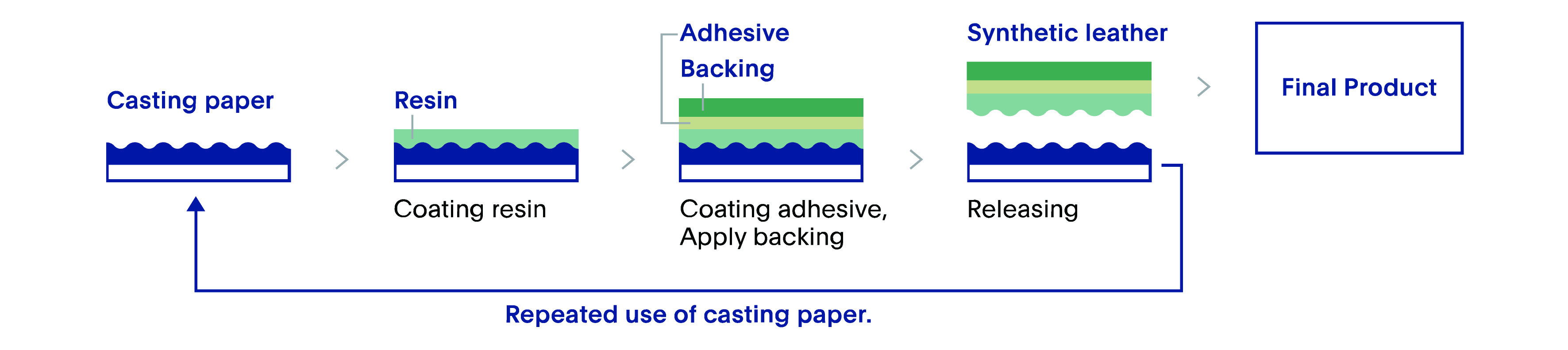

LINTEC provides a wide range of casting papers (release papers) that serve as molds for replicating the surface texture of genuine leather in the manufacturing of synthetic leather used for shoes, bags, clothing, furniture and other items. In recent years, synthetic leather is attracting attention in a variety of industries for its ease of handling, light weight, and material functionality, as well as from the perspective of animal welfare. This renewed interest has created an urgent need for LINTEC to strengthen its capacity to respond to customers and its competitive edge in the marketplace.

For these reasons, LINTEC has invested approximately 4.8 billion yen in its Komatsushima Plant, the company's main manufacturing base for casting papers and release papers for adhesive products, to construct a new solar panel-equipped building and to install new coating equipment.

Synthetic leather manufactured using LINTEC casting paper

State-of-the-art Coating Equipment for Wide Widths

The growing global demand for wide bolts of synthetic leather, particularly for vehicle interiors, requires coating equipment that can accommodate these wide widths. LINTEC's newly installed equipment meets these requirements, offering high-speed, high-precision performance. The equipment uses a water-based coating system that does not require organic solvents. This contributes to a reduction in VOC (Volatile Organic Compounds) emissions, and production capacity at the facilities is expected to reach approximately 1.5 times that of conventional equipment.

The new equipment features extensive automation, including automatic mixing of the release agent (the coating material used on release papers) and automatic warehousing and unloading of base paper and products, which will help reduce manpower needs and improve efficiency.

LINTEC will utilize the strengths of the new equipment to increase production of casting papers, particularly wide width types. The company plans to expand its lineup for the manufacture of high-grade synthetic leather, providing subtly different surface glosses and textures, including matte and glossy, to capture new demand for these papers. The new facilities are to be completed at the end of August, and manufacturing operations are scheduled to begin in September. The company also intends to further expand sales of casting papers for synthetic leather, focusing on overseas markets including India, China, Europe, and North America.

New building

New coating equipment

Synthetic leather manufacturing process using LINTEC casting papers (synthetic leather manufacturer)

Overview

- Komatsushima Plant

- Location: Komatsushima City, Tokushima Prefecture

- Operations launched: July 1967

- Site area: Approx. 40,000m2

* 11,000m2 of which constitute expansion under current project (fixed-term business lease) - Employees: 90 (as of July 31, 2025)

- New building (No. 3 Building)

- Construction: Three-story steel-framed building

- Total floor area: 4,406m2

- Construction area: 3,324m2

- Solar power generation system (rooftop): Approx. 340kW output

- New coating equipment

- Coating method: Water-based (solvent-free) coating type

- Products: Casting papers for synthetic leather, release papers for adhesive products, casting papers for carbon fiber composite materials, etc.

- Operation launched: September 2025

The contents of the News Release are as of the announcement date. Please note that they may differ from the latest information.