- HOME

- Topics

- News Release

- 2020

January 31, 2020

Contributing to the conservation of petroleum resources by adopting botanically-derived raw materials for facestock, and producing thinner film

Over-laminate film with biomass facestock

Acquires Biomass Mark certification for use as a facestock for laminate films

LINTEC offers a range of over-laminate films which can be affixed to the printing surface of labels to give added durability and enhanced aesthetic design features. The latest addition to the lineup is a new over-laminate film utilizing biomass facestock, for which LINTEC has acquired Biomass Mark certification under a program operated by The Japan Organics Recycling Association (JORA). The new film is to be launched both in Japan and overseas as of February 3.

New over-laminate film utilizes facestock made using plant-derived raw materials

LINTEC is continuously investing its efforts into developing (and increasing sales of) products that contribute to decreasing environmental impact. As one aspect of these efforts, we have expanded our lineup of products utilizing plant-derived raw materials, such as labelstocks that make use of biomass adhesives.

On this occasion, LINTEC has added a new gloss type over-laminate film that adopts botanically-derived raw materials for its facestock, which acts as the base film. Affixing the film to the printing surface of label gives added durability and enhanced aesthetic design features. The new item will be launched both in Japan and overseas as of February 3.

The new film can be used to laminate a wide range of items, including labels for food products and cosmetics

Contributing to the reduction of petroleum resource usage by making thinner facestock

The new item adopts a biomass facestock for which LINTEC has obtained Biomass Mark certification, under a scheme operated by The Japan Organics Recycling Association (JORA, certification number:190132). This facestock achieves a biomass ratio* of 20%, without degrading functionality in comparison with conventional over-laminate films. Since the facestock is also thin, at a thickness of only 12µm, it also contributes to reducing usage of fossil (petroleum) resources. Moving forward, LINTEC will continue to strive to develop and actively propose environmentally-friendly products.

- Biomass ratio: The percentage of biomass raw materials contained in a product(percentage of dry weight)

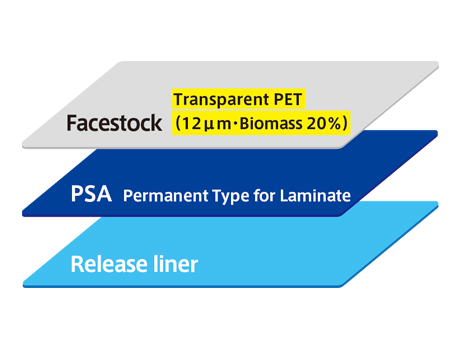

Figure showing the structure of over-laminate film

Biomass Mark:

A mark certified by the Japan Organics Recycling Association.Utilizing biomass (bio: biological resources, mass: quantity), which is an organic resource derived from renewable organisms, it is a landmark for products that meet quality and standards.

Lineup of products made using biomass raw materials

・ Over-laminate film with biomass facestock [New Item]

This over-laminate film adopts a biomass facestock made using botanically-derived raw materials, for which LINTEC has obtained Biomass Mark certification, under a scheme operated by The Japan Organics Recycling Association (JORA). This substrate achieves a biomass ratio* of 20% without degrading functionality in comparison with conventional over-laminate films, and affixing this film to the printing surface of a label gives added durability and enhanced aesthetic design features.

・ Biomass adhesive labelstocks

LINTEC has obtained Biomass Mark certification for the adhesive layer in its labelstocks, which adopt an adhesive made from plant-derived raw materials. The lineup includes four super-strength adhesive type items with facestocks made from environmentally friendly film--produced using over 80% recycled PET plastic made from collected PET bottles--and typical deposited film (biomass ratio: 10%); two items produced using emulsion-type adhesives (biomass ratio: 10%); and one item which is suitable for affixing under low temperature conditions and on uneven surfaces (biomass ratio: 20%).

The contents of the News Release are as of the announcement date. Please note that they may differ from the latest information.