- Small

- Large

Providing Value to Customers(2)

Quality Assurance

LINTEC Group is based on the company motto “Sincerity and Creativity.” Individual employees work on manufacturing with an awareness of quality, the environment and safety. We are taking on new challenges, never satisfied with the status quo, to deliver safer, more reliable products. The LINTEC Group continues to address challenges in manufacturing for the future.

Quality Assurance System

The LINTEC Group has established a quality assurance system based on ISO 9001★. In Japan, we have integrated the quality assurance systems of six divisions into a group-wide QMS. For group companies outside Japan, the quality assurance system has been set up and put into operation at 12 business sites.

In fiscal 2022, LINTEC started further quality improvement initiatives with reinforced quality assurance and quality control and effective QMS operation under the new quality assurance system.

Under the new organization, we will enhance collaboration between business activities and quality assurance and the integration of QMS activities, with the aim of building a customer-oriented quality assurance system founded on manufacturing.

Acquisition of ISO 9001 certification

Slide to view.

| FY2019 | FY2020 | FY2021 | FY2022 | ||

|---|---|---|---|---|---|

| Number of sites certified | 16 | 16 | 16 | 16 | |

| By region | Japan | 5 | 4 | 4 | 4 |

| Asia | 8 | 8 | 8 | 8 | |

| Americas | 3 | 4 | 4 | 4 | |

- ★ISO 9001: The international standard for quality management systems (QMS).

Quality Accident Prevention and Education

The LINTEC Group considers it is important to integrate the quality management system (QMS) into business processes and implement the QMS effectively so as to maintain and improve the quality of products and services and prevent quality-related accidents.

To this end, LINTEC provides education programs in three stages: basic training for understanding QMS requirements, operation training for implementing the QMS effectively, and training for developing internal auditors.

Efforts are also focused on reinforcement of the quality management system. As a new initiative starting from fiscal 2022, LINTEC held quality management training using the statistical problem solving techniques as a tool to deepen understanding of the concept of quality control in the manufacturing process and improve the ability to detect and analyze defects.

Training for data management using BI tools★ is also conducted.

We will continue these activities, aiming to provide products and services that are trusted by customers.

- ★BI (Business Intelligence) tools: Tools to help prompt decision-making by gathering and analyzing a large amount of accumulated data.

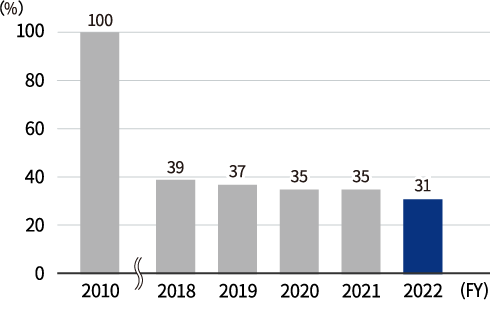

Ratio of quality accidents

Slide to view.

- Notes:1. Ratio of quality accidents at LINTEC CORPORATION, TOKYO LINTEC KAKO, INC., and SHONAN LINTEC KAKO, INC.

2. Ratio to the number recorded in fiscal 2010 as 100%.

VOICE My Next Stage

MACTAC supports a partnership in safety, quality and operational excellence in our products to support our team and our customers’ team. Our Quality Policy states that the success of MACTAC relies on a sustainable quality culture at the core of all its processes and business activities. This is the foundation MACTAC builds its trust on with its customers, suppliers and partners. MACTAC is committed to developing and manufacturing quality, environmentally friendly and safe products that exceed our customer expectations. Our goal is to provide today’s needs and anticipate tomorrow’s. MACTAC is committed to its Quality Management System through compliance, objectives and continuous improvement through employee involvement and teamwork. With this goal in mind, the team has been focusing on three key areas of our Quality Management System.

- ISO 9001: 2015 Quality management system

Our Spinnaker Troy, Ohio manufacturing facility is currently in the process of receiving their ISO 9001 certification and scheduled for 3rd quarter 2023. Once this is completed, all of our domestic manufacturing facilities will be ISO 9001:2015 certified. - Quality Summit

The MACTAC and Spinnaker Quality Leaders for each area of manufacturing, supplier management, claims and regulatory meet to review and build our quality plans for the current and future year, during our annual Quality Summit. - Project LINKS

LINKS will provide a new architecture for managing quality in our ERP (Enterprise Resources Planning) system, across our manufacturing facilities and finishing and distribution centers. Our team has aligned on specific quality applications that will be used across the network. Developments have been made that have allowed us to challenge the current processes for improvements, promote standardization, enhance customer facing documents and a variety of other areas.

We strive to constantly improve our customer’s overall experience with MACTAC.

Director of Quality, MACTAC AMERICAS, LLC

Assessment of Health and Safety Impacts

The LINTEC Group handles many materials for industrial products, which relate to a large component of its businesses. Being aware that some of the materials we offer contain hazardous chemicals, we work to ensure that such materials will never affect users, specifically by selecting appropriate raw materials in compliance with standards and guidelines based on the RoHS Directive★, the Industrial Safety and Health Act, and other regulations, and takes careful measures to prevent contamination during manufacturing processes. In fiscal 2022, no instances of noncompliance or violation were reported in relation to our business activities. With regard to the newly added restricted substances, we will conduct investigations into substances contained in them, and will consider the use of alternatives if necessary.

- ★RoHS Directive: Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment issued by the EU.

Communicating with Customers

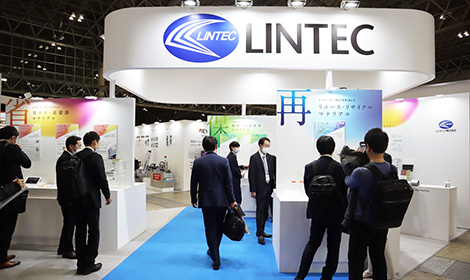

Exhibiting at Exhibitions in and Outside Japan

In order to communicate with even more customers, LINTEC Group actively participates in exhibitions held in and outside Japan. In fiscal 2022, LINTEC took part in a total of 35 exhibitions and received valuable feedback on its products and technologies.

Fiscal 2022 Exhibitions

Slide to view.

| Japan | Outside Japan |

|---|---|

|

|

VOICE My Next Stage

We introduce and promote sales of our environment-friendly labelstock, which our company has actively developed through initiatives such as responding to demand for non-plastic or less-plastic products; resource recycling (recycling of containers and packages); and the use of solvent-less and plant-derived materials. In line with growing needs and interest in various industries, especially in the cosmetics and daily commodities industries, we released a catalog of environment-friendly label materials that lists only environment-conscious materials in February 2023. The catalog has been used by many people. We will continue with efforts to grasp market demand and advance approaches in cooperation with our sales department and research centers, in order to offer and propose label materials that are consistent with the sustainability policies of our customers.

Technical Planning Office

- Message from the President

- Concept and Systems

- Highlight: Initiatives for the Reduction of CO2 Emissions

- Environmental Report

- Environmental Management System

- Developing Environmentally Friendly Products

- Climate Change Mitigation and Adaptation

- Realization of a Recycling-oriented Society

- Co-existence with Nature

- Management of Environmentally Hazardous Substances

- Environmental Accounting

- Environmental Data of Group Companies Outside Japan

- Relationship between LINTEC and the Environment

- Social Report

- Providing Value to Customers

- Cooperating with Suppliers

- Together with Employees (Human Rights / Employment)

- Together with Employees (Human Resource Development)

- Together with Employees (Safety and Disaster Prevention)

- Together with Local Communities

- Together with Shareholders

- Communicating with Stakeholders

- Governance Report

- SDGs-related Initiatives

- CSR Activities at Group Companies Inside and Outside of Japan

- Information Disclosure Based on TCFD Recommendations

- Corporate Policies

- Reporting Policy

- Performance Data

- GRI Index

- Message from Outside Director

- Third-Party Verification

- External Evaluations

- Download Report