- Small

- Large

Climate Change Mitigation and Adaptation (2)

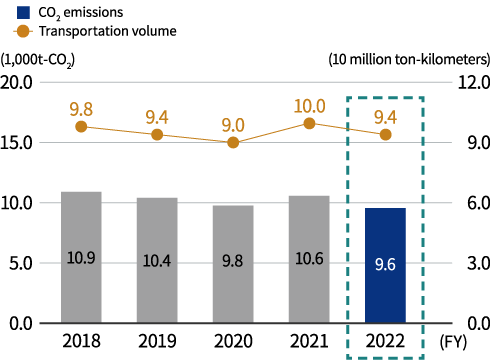

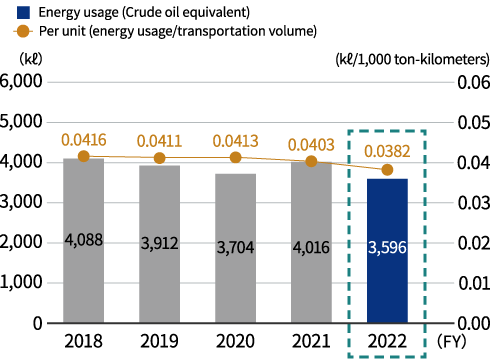

Efforts in Distribution

In fiscal 2022, transportation volume decreased by 5.5% (5,531,000 ton-kilometers★) from the previous year. For CO2 emissions, we achieved a reduction of 10.5% (1,119 t-CO2) partly due to the revision of the ton-kilometer calculation method and the introduction of a rating system for domestic vessels. The average emissions intensity related to energy use over the past five years decreased by around 2.1%.

In the future, we will work on optimizing transportation efficiency and modal shift by further strengthening collaboration with logistics companies, affiliated companies, and our plants.

- ★Ton-kilometers: A unit of cargo transport amounts, computed by multiplying the cargo tonnage by the transportation distance. Transporting 1 ton of cargo over a distance of one kilometer equals one ton-kilometer.

CO2 emissions and transportation volume in distribution

- Note:Calculated according to the emission intensity database.

Energy usage

- Note:Calculated on the basis of the Energy Conservation Act (Measures Pertaining to Consigners)

Response to TCFD Recommendations

In FY2021, we considered “risks” and “opportunities” related to climate change with a target period of 2030 (medium-term), but in fiscal 2022, we added a long-term period targeting 2050 (long-term) and analyzed the 2°C or below 1.5°C, and 4°C scenarios while advancing the formulation of a global vision for domestic businesses.

As a result, we identified and revised “transition risks and physical risks,” and “opportunities” in accordance with the TCFD recommendations.

Furthermore, regarding financial impact, we calculated quantitative impact and examined its degree of impact on business and countermeasures, and worked to improve the disclosed information on “strategy” both qualitatively and quantitatively.

- Message from the President

- Concept and Systems

- Highlight: Initiatives for the Reduction of CO2 Emissions

- Environmental Report

- Environmental Management System

- Developing Environmentally Friendly Products

- Climate Change Mitigation and Adaptation

- Realization of a Recycling-oriented Society

- Co-existence with Nature

- Management of Environmentally Hazardous Substances

- Environmental Accounting

- Environmental Data of Group Companies Outside Japan

- Relationship between LINTEC and the Environment

- Social Report

- Providing Value to Customers

- Cooperating with Suppliers

- Together with Employees (Human Rights / Employment)

- Together with Employees (Human Resource Development)

- Together with Employees (Safety and Disaster Prevention)

- Together with Local Communities

- Together with Shareholders

- Communicating with Stakeholders

- Governance Report

- SDGs-related Initiatives

- CSR Activities at Group Companies Inside and Outside of Japan

- Information Disclosure Based on TCFD Recommendations

- Corporate Policies

- Reporting Policy

- Performance Data

- GRI Index

- Message from Outside Director

- Third-Party Verification

- External Evaluations

- Download Report