- Small

- Large

Climate Change Mitigation and Adaptation

The LINTEC Group is committed to carrying out various environmental activities to acquire opportunities from and adapt to climate change, which poses a major risk to the continuation of its business activities.

Efforts in Manufacturing

Status of Compliance with Japanese Energy Conservation Law

Energy use by the entire LINTEC Group★ in Japan exceeds 1,500 kl of crude oil equivalent each year. As a result, the Group was designated as a “specified business operator,” pursuant to the provisions of the Act on the Rational Use of Energy (“the Energy Conservation Act”) in Japan, and is required to improve its energy use per production unit as well as its weighted electricity use per production unit (for reducing peak hour demand) by 1% per year. Additionally, many LINTEC plants were designated as “specified business establishments” whose energy use is above 1,500 kl of crude oil equivalent. Since nine plants in Japan account for 95% of the Group’s total energy consumption, it is important for each plant to take measures to reduce energy use. In fiscal 2022, the LINTEC Group in Japan implemented a variety of activities, such as effective operation of production facilities, introduction of high-efficiency boilers, and introduction of solar power generation systems for internal use. Due to the progress in energy saving, some business sites that have been designated as “specified business locations” may be reclassified to a different designation category or removed from the designation.

- ★LINTEC Group in Japan: LINTEC CORPORATION and its sales offices; LINTEC SIGN SYSTEM, INC. (on the premises of the LINTEC CORPORATION Head Office); SHONAN LINTEC KAKO, INC.; LINTEC SERVICES, INC.; LINTEC CUSTOMER SERVICE, INC. (on the premises of LINTEC COPORATION Ina Technology Center); and TOKYO LINTEC KAKO, INC.

Energy Savings Promotion Committee

To comply with the Energy Conservation Act, the LINTEC Group★ in Japan collects monthly data on energy consumption of individual sites under the direction of the LINTEC Energy Savings Promotion Committee. In fiscal 2021, the LINTEC Group in Japan implemented corporate-wide energy-saving measures aimed at improving its energy use per production unit. We request the respective plants to submit their plans and measures to achieve the target of 1% reduction per production unit, and compile data on the progress and results of these measures. Moreover, energy-saving practices that have proven effective are applied to other production sites.

- ★LINTEC Group in Japan: LINTEC CORPORATION and its sales offices; LINTEC SIGN SYSTEM, INC. (on the premises of the LINTEC CORPORATION Head Office); SHONAN LINTEC KAKO, INC.; LINTEC SERVICES, INC.; LINTEC CUSTOMER SERVICE, INC. (on the premises of LINTEC COPORATION Ina Technology Center); and TOKYO LINTEC KAKO, INC.

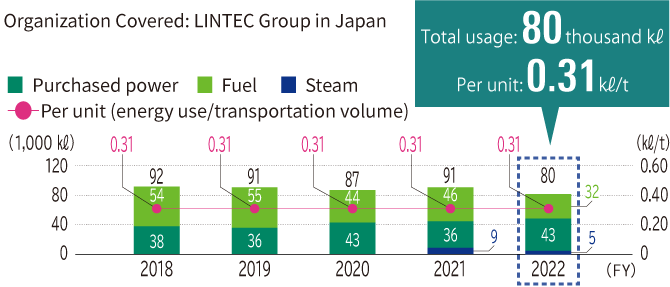

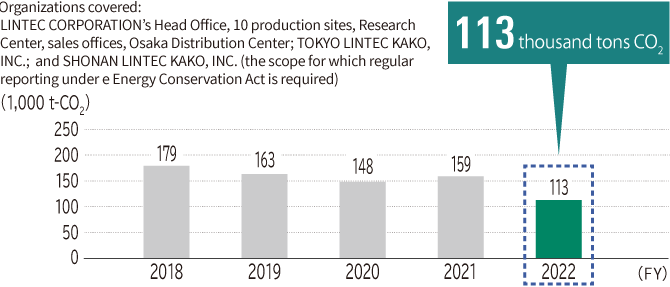

Total Energy Use and CO2 Emissions

In fiscal 2022, total energy use (crude oil equivalent, covered by the Energy Conservation Act) for the LINTEC Group in Japan decreased by 12% from the previous year due to progress in energy conservation efforts and a decrease in production volume. Energy use per unit of production increased by 2.5% to 0.31 kl per ton. CO2 emissions in fiscal 2022 were 113,000 t-CO2, down from 159,000 t-CO2 in fiscal 2021. In fiscal 2023, we will further promote the use of low-carbon electric power.

Slide to view.

| FY2019 | FY2020 | FY2021 | FY2022 | |

|---|---|---|---|---|

| Green electricity purchased (GWh) | 36 | 34 | 35 | 80 |

| Calorie equivalent (thousand GJ) | 352 | 335 | 342 | 778 |

| CO2 reduced by green electricity (thousand tons) | 16.9 | 16.1 | 16.0 | 33.8 |

| Reduction effects of investment in reducing CO2 (t-CO2) (Cumulative values from fiscal 2019) |

43 | 2,774 | 7,140 | 9,372 |

- Notes:1. Calculated on the basis of the Energy Conservation Act (CO2 emissions coefficient of the business operator)

2. Calculated on the basis of the Energy Conservation Act (Act on Promotion of Global Warming Countermeasures)

Total energy use (crude oil equivalent)

- Note:Fuel means gasoline, light oil, kerosene, Bunker-A oil, liquid natural gas (LNG), liquid petroleum gas (LPG), and utility gas.

CO2 Emissions

- Notes:1. The fuel-derived CO2 emissions coefficient for each fiscal year uses the coefficient stipulated in the Energy Conservation Act. For CO2 emissions related to the use of purchased electricity, LINTEC uses the adjusted emission coefficient of the electric power company that supplies electricity to the facilities concerned.

2. The emissions shown above are CO2 emissions from fossil fuels.

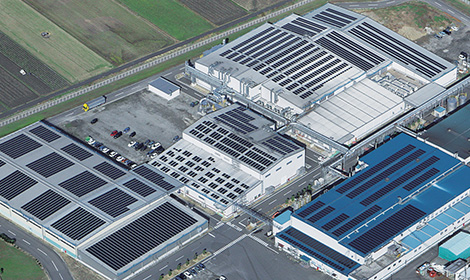

Solar Power

In addition to the Doi Plant and the Agatsuma Plant, LINTEC installed photovoltaic power generation systems for internal use at the Ina Technology Center, TOKYO LINTEC KAKO, INC., the Chiba Plant, Kumagaya Plant, and Mishima Plant. Additional systems were installed at the Doi Plant.

Using the national average coefficient announced in January 2023, the reduction effect is equivalent to 1,586 t-CO2.

Introduction of Cogeneration Systems

LINTEC has introduced cogeneration systems that produce and supply electric power and heat from the heat source.

The Kumagaya Plant and Doi Plant have introduced gas engine cogeneration systems, which are systems that use LNG (Liquefied Natural Gas) and other types of fuel and generate and supply electric power to operate various production facilities. These plants collect heat generated at the time of power generation in order to reclaim steam using an exhaust heat recovery boiler and run absorption chillers to produce cooling water.

The Doi Plant installed additional systems and started operation in April 2023.

Efforts to Prevent the Leakage of Fluorocarbons

Manufacturing sites are equipped with a number of package air conditioners and chillers that use fluorocarbon refrigerants. LINTEC creates a list of such equipment in compliance with the Fluorocarbon Emissions Control Act and conducts required inspections to prevent fluorocarbon leaks during use of the equipment.

When it comes time to dispose of the equipment, we entrust appropriate service providers with the task to ensure safe recovery of the fluorocarbon refrigerants. We will continue to ensure proper use and management in compliance with laws and regulations.

Reducing Power Used for Lighting

The LINTEC Group continuously encourages energy-saving activities. While promoting the introduction of LED lighting as planned, we are working to reduce electricity use through activities such as turning off lights when not necessary. In fiscal 2022, these activities were carried out in an ongoing manner.

VOICE My Next Stage

Within MACTAC, Simply Sustainable is more than a brand. It’s our initiative to choose environmental best practices so they can be ingrained in everything we do and simply become a part of who we are. And it simply starts with building a culture that values and celebrates responsible innovation.

We accomplish this through focus on our four main sustainability pillars - sourcing, manufacturing, R&D, and diversity and equal rights. In our manufacturing facilities, it is a two-fold focus, on waste and CO2 reduction. Coated product waste is either recycled or sent to waste-to-energy plants. We maximize our efforts to minimize our waste production and streamline our production process to reduce our carbon footprint. We’ve also made significant investments in our CO2 reduction journey, such as LED lighting installation within our coating facilities (completed in 2022) and our finishing facilities (to be completed in 2023). Updating the lighting not only decreases our CO2 emissions, but it also reduces maintenance time, waste disposal on used bulbs, and creates a better lit environment for our employees.

Sustainability Manager, MACTAC AMERICAS, LLC

- Message from the President

- Concept and Systems

- Highlight: Initiatives for the Reduction of CO2 Emissions

- Environmental Report

- Environmental Management System

- Developing Environmentally Friendly Products

- Climate Change Mitigation and Adaptation

- Realization of a Recycling-oriented Society

- Co-existence with Nature

- Management of Environmentally Hazardous Substances

- Environmental Accounting

- Environmental Data of Group Companies Outside Japan

- Relationship between LINTEC and the Environment

- Social Report

- Providing Value to Customers

- Cooperating with Suppliers

- Together with Employees (Human Rights / Employment)

- Together with Employees (Human Resource Development)

- Together with Employees (Safety and Disaster Prevention)

- Together with Local Communities

- Together with Shareholders

- Communicating with Stakeholders

- Governance Report

- SDGs-related Initiatives

- CSR Activities at Group Companies Inside and Outside of Japan

- Information Disclosure Based on TCFD Recommendations

- Corporate Policies

- Reporting Policy

- Performance Data

- GRI Index

- Message from Outside Director

- Third-Party Verification

- External Evaluations

- Download Report