- Small

- Large

Highlight: Initiatives for Reduction of CO2 Emissions

As one of the key initiatives of the long-term vision “LSV 2030” is to “Solve social issues,” the LINTEC Group is dedicated to initiatives for the environment, making group-wide concerted efforts. In this highlight, let me explain some initiatives that are being conducted by the Production, Research and Sales Divisions concerning measures to reduce CO2 emissions aiming at achieving “carbon neutrality” by 2050, and “curbing the release of volatile organic compounds (VOC) into the atmosphere (zero by 2030).”

Production Division

Formulating a Capital Expenditure Plan in Line with the Long-term Vision

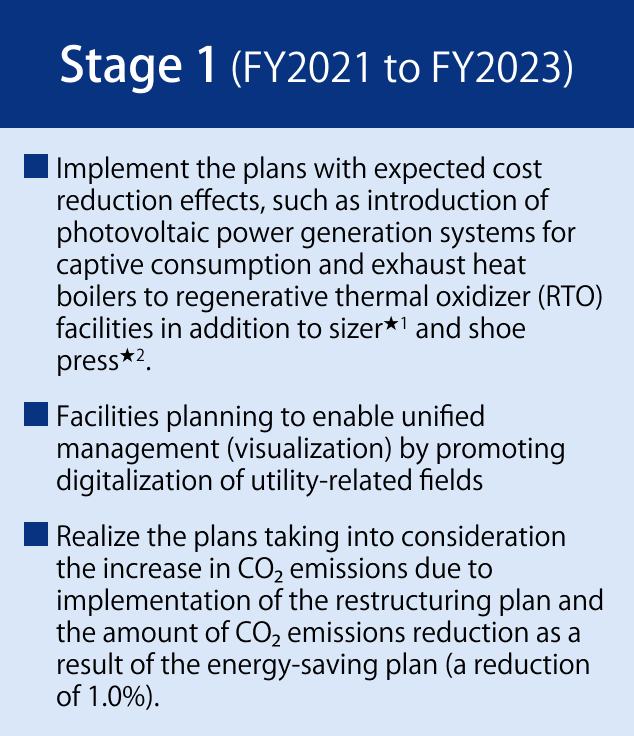

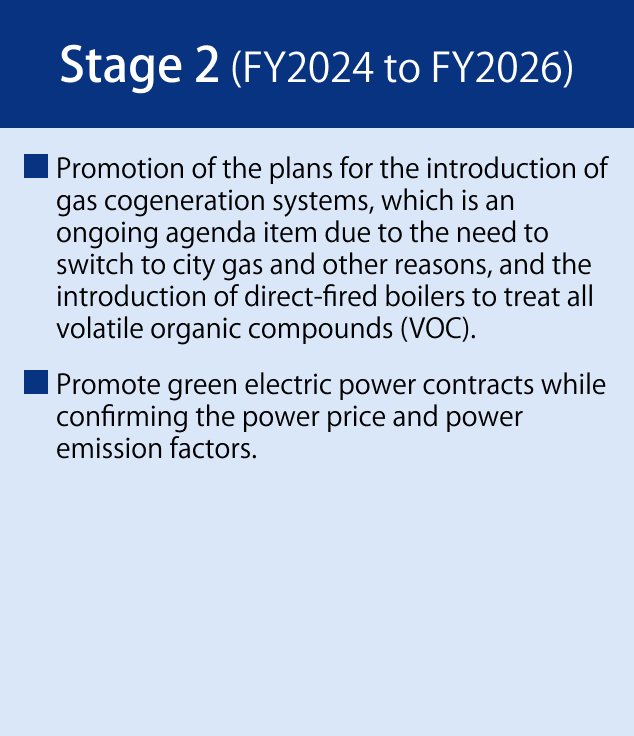

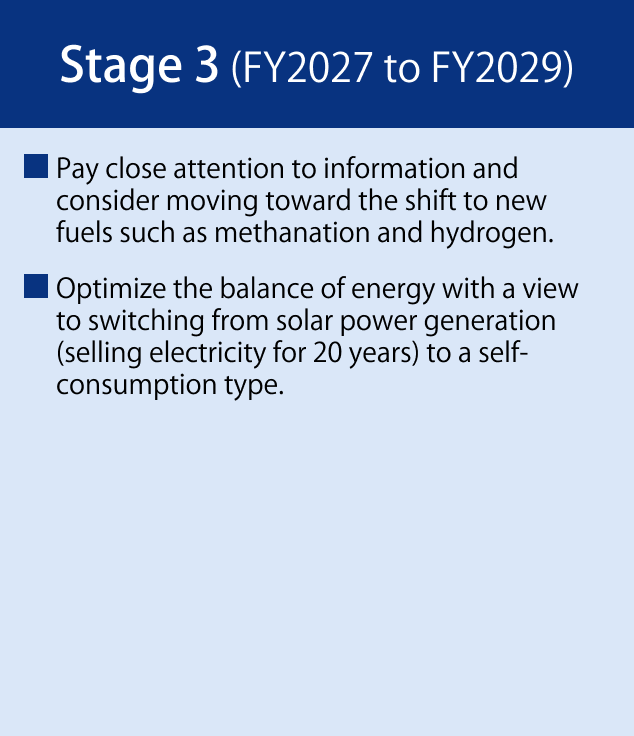

Recognizing the reduction of CO2 emissions as materiality, the LINTEC Group implements various measures from the aspect of production facilities, and formulates and promotes capital expenditure plans on a global scale, including overseas Group companies, in line with the medium-term business plan under the long-term vision “LSV 2030.” As for “LSV 2030 - Stage 1 (FY2021 to FY2023),” we plan to invest approximately 8.8 billion yen in the introduction of photovoltaic power generation systems for captive consumption and the improvement of various production facilities, totaling approximately 19.5 billion yen up to FY2030, the final year of “LSV 2030 - Stage 3.” And, together with the reduction of emissions, we are also considering pursuing cost-effectiveness as a company.

- ★1Sizer: Equipment for lightweight coating (applies chemicals to the surface of the sheet as necessary) shortens drying time, which helps reduce energy usage the dry process.

- ★2Shoe press: Equipment capable of squeezing more water out of the sheet than before, This helps increase dehydration efficiency and reduce energy usage in the drying process.

Introduction of New Facilities in FY2022

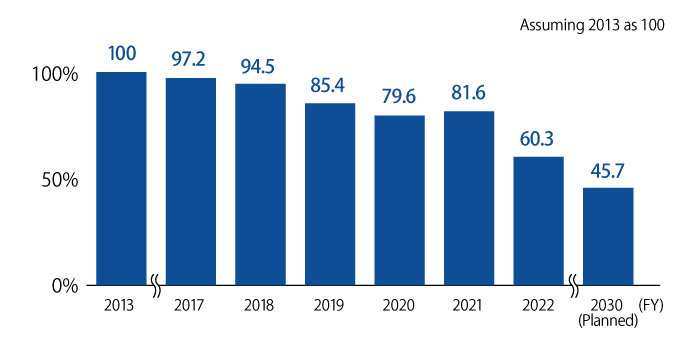

CO2 emissions for FY2022 in the entire LINTEC Group were 177,928t-CO2, a decrease of 39.7% compared to FY2013. A large volume of CO2 in particular is discharged in the drying process of the paper machine when specialty paper is made. As a result of the introduction of a shoe press at the Kumagaya Plant (Saitama Prefecture), the main production base, and a sizer at the Mishima Plant (Ehime Prefecture), it is expected that both energy use and CO2 emissions will be further reduced.

We also focus on the introduction of photovoltaic power generation systems for captive consumption, introducing them to the Tatsuno Plant, Kumagaya Plant, Doi Plant and Komatsushima Plant in FY2022. An annual reduction of 1,000t-CO2 is expected. We have completed the introduction of this system at almost all production bases in Japan, and we will continue to introduce it as much as possible. Other than the above, we have implemented various measures for the reduction of CO2 emissions such as a review of production processes, renovation of the exhaust heat recovery method, introduction of highly efficient boilers, and stopping the use of solvents.

Actual reduction of CO2 emissions by the LINTEC Group

Toward the Achievement of Our Goals

In FY2023, the final year of “LSV 2030 - Stage 1,” we will review and optimize the plan by examining the actual quantity reduced and conducting interviews at each plant with the aim of putting into practice more effective reduction measures toward Stages 2 and 3. In parallel with the above, we are considering countermeasures to prevent in advance the increase in emissions as a result of energy saving through “scrap and build,” which is to be implemented at plants in the future, and innovation of production processes for the purpose of higher quality, higher efficiency and labor-saving. We also plan to realize carbon neutrality at some plants prior to achieving the goals in FY2030. Going forward, we will proactively implement LINTEC’s group-wide concerted efforts to respond to rising demands.

Production Division

Research & Development Division

Expected Environmental Friendliness and Promotion of Development

Since we often see and hear terms related to the environment, such as global warming, air pollution and water pollution, our awareness of these issues has been rising more than before.

We understand that the value of so-called research & development work is to create performance that is required or will be required at an acceptable cost. This is the value that a product must have, but we believe that environmental friendliness should be added as well.

This means that, for example, we can add easy-to-recycle features by making mono-material, by using the same material for all components and substituting with bio-mass materials. In addition, although this is not limited to the themes and laboratories that I am in charge of, in order to reduce actual CO2 emissions, we are working to reduce the thickness of the base material, which is the constituent material of the adhesive label, and apply less adhesive. Furthermore, we are reducing the amount of organic solvents used in the manufacturing process or replacing them with water to create emulsions.

LINTEC’s Development of Hot Melt-type Adhesives, Contributing to the Reduction of CO2 Emissions through the Non-use of Organic Solvents

There are various methods and means when it comes to environment-friendly treatments. Among them, the “HVT Series” is a hot melt adhesive★ that does not use organic solvents in the manufacturing process.

Emulsified adhesives have an advantage from the viewpoint of environmental friendliness in that they do not use organic solvents, but the disadvantage is that they are extremely difficult to achieve thick adhesive layers. On the other hand, hot melt-type adhesives have the advantage of being easy to manufacture when the adhesive layer needs to be thickened, enabling coverage of a wide range of products through mutual complementation.

- *Hot melt adhesive: An adhesive formulation that is applied while melting it with heat. Characteristics include less environmental impact due to not using organic solvents in the coating process, and less CO2 emissions due to no requirement for drying facilities.

Toward the Achievement of Our Goals

As mentioned above, in addition to continuing to consider the elimination of organic solvent use, we would like to realize development in which we will be able to propose replacement with more environment-friendly products, not to mention continuing to work to reduce the thickness of the base material and develop adhesives that use a smaller coating quantity by proactively selecting bio-mass materials. Many products I develop are familiar items we see and touch in our daily life, and I feel that, for example, “there will be no problem if a plastic item is replaced by a paper item for a specific use.” I would like to continue to develop eco-friendly products while making use of these daily experiences.

Product Research Department

Research Center of the Research & Development Division

Business Administration Division

Proposals for Environment-conscious Products to Satisfy Diversified Customer Demands

Toward the realization of a sustainable society, environmental awareness has risen in various fields, and needs for environment-friendly labels for a variety of products have also been increasing.

Labelstocks with low environmental impact include utilization of recycled materials, reduction of plastic usage (reduction of plastics)/replacement with paper materials (elimination of plastics), and use of biomass (living organisms) materials. In order to meet the various needs of our customers to reduce their environmental impact, LINTEC offers a wide lineup of labelstocks with lower environmental burden such as the “KINATH KP Series,” which is made of materials recycled from PET bottles, and the “PLALESS Series” which is a labelstock alternative to plastic based on our washing-resistant paper technology.

Expanding Solvent-free Products

In particular, we have received more and more inquiries on reducing CO2 emissions. One of our efforts in particular we have been focusing on is to reduce the amount of organic solvents used in the manufacturing process. As an example of our initiatives toward solvent-free adhesives, in 2020, we launched a product line in Japan that used “CHILL AT,” a hot melt adhesive★ developed by MACTAC AMERICAS, LLC, a U.S. subsidiary. Some companies have adopted this product due to its environmental performance, such as less CO2 emissions at the material and manufacturing stages compared to products using solvent-based adhesives, in addition to the added feature that the product can be attached in a cool or frozen environment. On the back of increasing needs for products that take into consideration reducing CO2 emissions, we have realized that hot melt adhesive products lead to the provision of value for customers (customer satisfaction). Furthermore, in 2023, we launched a product line that applies the new hot melt adhesive “HVT,” our proprietary development. In contrast to “CHILL AT,” which is excellent in attachment performance in a low-temperature environment, “HVT” has excellent attachment performance under normal to high temperatures, and is applicable for wider use, from daily necessities to cosmetics and medical products.

Toward the Achievement of Our Goals

Going forward, regarding initiatives for products with low environmental burden other than solvent-free products, we will work on reducing the coat thickness of materials used, which will lead to a reduction in plastic use, and recycling of release paper, etc. Furthermore, LINTEC not only develops labelstocks but labeling machines as well, and we are proposing thin film labeling machines that enable labeling using PET 12μm base materials, which had been considered difficult until now. We plan to focus on developing and proposing thin film labelstocks compatible with this thin film labeling machine. In addition, we are examining ways to collect, recycle, and reuse release paper that becomes waste after the label is used.

Technical Planning Office

- Message from the President

- Concept and Systems

- Highlight: Initiatives for the Reduction of CO2 Emissions

- Environmental Report

- Environmental Management System

- Developing Environmentally Friendly Products

- Climate Change Mitigation and Adaptation

- Realization of a Recycling-oriented Society

- Co-existence with Nature

- Management of Environmentally Hazardous Substances

- Environmental Accounting

- Environmental Data of Group Companies Outside Japan

- Relationship between LINTEC and the Environment

- Social Report

- Providing Value to Customers

- Cooperating with Suppliers

- Together with Employees (Human Rights / Employment)

- Together with Employees (Human Resource Development)

- Together with Employees (Safety and Disaster Prevention)

- Together with Local Communities

- Together with Shareholders

- Communicating with Stakeholders

- Governance Report

- SDGs-related Initiatives

- CSR Activities at Group Companies Inside and Outside of Japan

- Information Disclosure Based on TCFD Recommendations

- Corporate Policies

- Reporting Policy

- Performance Data

- GRI Index

- Message from Outside Director

- Third-Party Verification

- External Evaluations

- Download Report