- Small

- Large

Co-existence with Nature

As an initiative for coexistence with nature (reducing environmental impact on nature), LINTEC works on water conservation (water use, effluent treatment). We pay sufficient attention to water saving, recovery and reuse, compliance with effluent standards, and effluent water quality.

Reducing Water Usage and Effluent

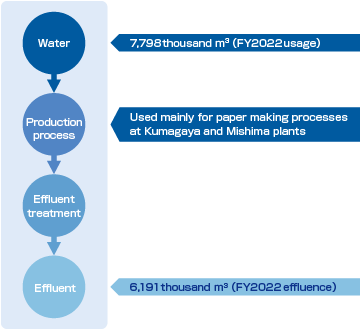

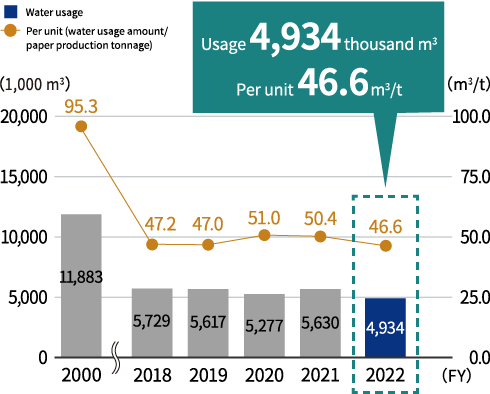

In fiscal 2022, LINTEC used 7,798,000 m3 of water. Of this amount, around 86% was used by the Kumagaya and Mishima plants, which comprise LINTEC’s Fine & Paper Products Operations. In fiscal 2022, water usage per unit of paper production was 46.60 m3/t, which achieved the target of a 1% reduction on a year-on-year basis.

The next target is a 4% reduction per unit of production by fiscal 2025 from the fiscal 2021 level. To achieve the target, the plants will make continued efforts to reduce water usage and effluent discharge in each process and prevent water leaks.

Moreover, plants that have paper machines are regulated by the Water Pollution Prevention Act. Additionally, the Mishima Plant, sited alongside the Akanoi river in Ehime Prefecture, is regulated by the Act on Special Measures for Conservation of the Environment of the Seto Inland Sea (Seto Inland Sea Act), while the Kumagaya Plant, situated next to the Arakawa river in Saitama Prefecture, is regulated by the Saitama Prefectural Ordinance for Environmental Preservation. Both satisfy effluent standards in their region.

Process from Water Intake to Effluent

Water usage data is calculated by source.

Slide to view.

| Category | FY2020 (thousand m3) | FY2021 (thousand m3) | FY2022 (thousand m3) |

|---|---|---|---|

| Total water usage | 7,951 | 7,718 | 7,798★ |

| ・Tap water | 531 | 509 | 540 |

| ・Industrial water | 3,660 | 3,715 | 3,383 |

| ・Groundwater | 3,760 | 3,494 | 3,876 |

| Effluent | 6,163 | 6,630 | 6,191 |

- Note: Water usage data is the sum of the figures for tap water, industrial water, and groundwater.

★ For detailed data, click here

Standards, methods and preconditions used

Tap water, groundwater, and industrial water are measured value

Water usage (Kumagaya and Mishima Plants)

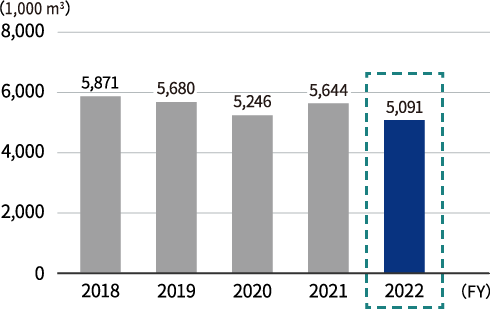

Effluent treated (Kumagaya and Mishima plants)★

- ★Total of flowmeter data for effluent treatment equipment installed at the Kumagaya and Mishima plants.

Water Quality Management (Effluent)

Effluent water quality at the Kumagaya and Mishima plants is as follows.

Effluent Water Quality (Fiscal 2022) (Kumagaya and Mishima plants)

Kumagaya Plant

Slide to view.

| Item | Effluent Water standards | Results | ||

|---|---|---|---|---|

| Maximum value | Average value | |||

| pH | 7.47 | 7.07 | ||

| Regulations on emission concentration | SS★1 | 60(50) or less | 42.90 | 11.73 |

| BOD★2 | 25 or less | 21.00 | 9.12 | |

| COD★3 | - | 43.20 | 22.09 | |

| Regulations on total emissions | COD (t/day) | 0.858 or less | 0.265 | 0.121 |

| Nitrogen (t/day) | 0.4068 or less | 0.1420 | 0.0023 | |

| Phosphorous (t/day) | 0.0418 or less | 0.0065 | 0.0007 | |

Mishima Plant

Slide to view.

| Item | Effluent Water standards | Results | ||

|---|---|---|---|---|

| Maximum value | Average value | |||

| pH | 5.8~8.6 | 6.0~7.7 | 6.77 | |

| Regulations on emission concentration | SS★1 | 80(60) or less | 44 | 4 |

| COD★2 | 90(65) or less | 89.2 | 25.0 | |

| Total nitrogen | 120 or less | 47.1 | 5.5 | |

| Total phosphorous | 16(8) or less | 0.83 | 0.04 | |

| Regulations on total emissions | COD (t/day) | 0.9431 or less | 0.4945 | 0.2365 |

| Nitrogen (t/day) | 0.3961 or less | 0.1990 | 0.0519 | |

| Phosphorous (t/day) | 0.0405 or less | 0.0014 | 0.0004 | |

- ★1SS: Suspended Solids

- ★2BOD: Biochemical Oxygen Demand

- ★3COD: Chemical Oxygen Demand

Biodiversity Conservation Initiatives

Upholding biodiversity conservation in the LINTEC Group Quality, Environmental and Business Continuity Policy, the LINTEC Group accordingly conducts biodiversity conservation activities in and outside of Japan.

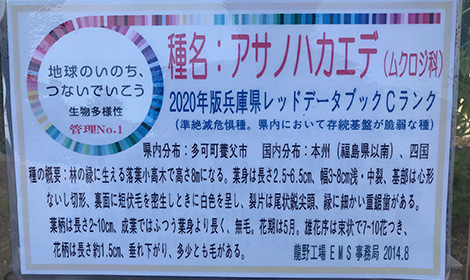

The Tatsuno Plant in Japan maintains and monitors conservation-listed deep-veined maple trees and uses red robin trees for greening purposes.

We will continue to promote the activities in collaboration with external companies.

The Chiba Plant covered the west wall of its warehouse with a green curtain in June 2022. Vines were seen to grow over four meters in length, as shown in the photo in August. We will continue to promote these activities that are close to us.

- Message from the President

- Concept and Systems

- Highlight: Initiatives for the Reduction of CO2 Emissions

- Environmental Report

- Environmental Management System

- Developing Environmentally Friendly Products

- Climate Change Mitigation and Adaptation

- Realization of a Recycling-oriented Society

- Co-existence with Nature

- Management of Environmentally Hazardous Substances

- Environmental Accounting

- Environmental Data of Group Companies Outside Japan

- Relationship between LINTEC and the Environment

- Social Report

- Providing Value to Customers

- Cooperating with Suppliers

- Together with Employees (Human Rights / Employment)

- Together with Employees (Human Resource Development)

- Together with Employees (Safety and Disaster Prevention)

- Together with Local Communities

- Together with Shareholders

- Communicating with Stakeholders

- Governance Report

- SDGs-related Initiatives

- CSR Activities at Group Companies Inside and Outside of Japan

- Information Disclosure Based on TCFD Recommendations

- Corporate Policies

- Reporting Policy

- Performance Data

- GRI Index

- Message from Outside Director

- Third-Party Verification

- External Evaluations

- Download Report