- Small

- Large

Management of Environmentally Hazardous Substances

The LINTEC Group complies with various environment-related laws and regulations in and outside Japan and strives to properly manage environmentally hazardous chemical substances. In Japan, we monitor emissions of VOC★1 and substances designated under the PRTR law★2. In particular, we focus our efforts on reducing toluene, which LINTEC uses in particularly large amounts.

- ★1VOC: VOC stands for volatile organic compounds. VOC collectively refers to organic compounds that become gas in the atmosphere.

- ★2PRTR: Formally named the Act on Confirmation, etc. of Release Amounts of Specific Chemical Substances in the Environment and Promotion of Improvement to the Management Thereof.

Compliance with PRTR

In fiscal 2022, LINTEC used 5,625 tons of toluene, xylene, and other substances designated under the PRTR law.

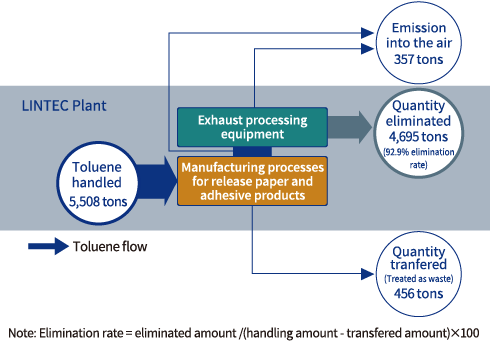

Among them, toluene accounted for the largest portion of the total amount, standing at 5,508 tons, down 1,436 tons from the previous year. Emissions of toluene into the atmosphere came to 357 tons, down 77 tons from the year before, and the transferred amount was 456 tons, down 60 tons. The decreases in the overall amounts of use and emissions were due to the promotion of suspension of the use of solvents and a decrease in production.

LINTEC has installed treatment facilities to reduce atmospheric emissions of organic solvents, and is making efforts to maintain their performance, which include conducting checks and cleaning and measuring emissions concentrations on a regular basis. LINTEC will also introduce new treatment facilities with high treatment efficiency, such as enrichment equipment for low-concentration solvent gas, which can not be treated with existing facilities. In addition, we are advancing formulation of release agents and suspension of the use of solvents for adhesives, thereby reducing the amount of use of such substances.

Emission and transfer of toluene FY2022

Change in emission and transfer of toluene

Slide to view.

| FY2018 | FY2019 | FY2020 | FY2021 | FY2022 | |

|---|---|---|---|---|---|

| Toluene handled(t) | 7,919 | 7,652 | 6,614 | 6,800 | 5,508 |

| Emission into the air(t) | 489 | 464 | 399 | 434 | 357 |

| Quantity eliminated(t) | 6,901 | 6,825 | 5,719 | 5,851 | 4,695 |

| Elimination rate(%) | 93.4 | 93.8 | 93.5 | 93.1 | 92.9 |

| Quantity transferred (t)

(Treated as waste) |

529 | 363 | 496 | 516 | 456 |

- Note:Elimination rate=eliminated amount (handing amount-transferred amount)×100

Management of Chemical Substances, Compliance with EU Regulations

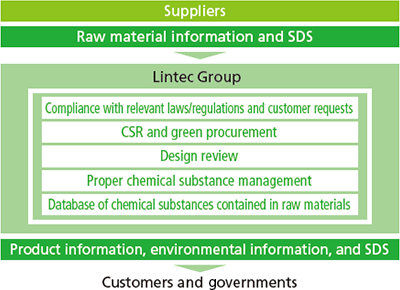

LINTEC has specified substances subject to environmental impact examinations, and examines these substances in the raw materials it purchases. The company properly grasps and manages its use of chemical substances to comply with related laws and regulations, and communicates information to customers.

Under the REACH Regulation★, additional substances have been included in the Candidate List of substances of very high concern (SVHCs), for which information must be communicated. As a result of the 29th update, there are now a total of 235 SVHCs on the List (as of June 14, 2023).

As new substances are added to the List in the future, we will promptly obtain the proper information and take action accordingly.

We are also switching over to materials containing no phthalate esters to provide products that are friendly to the environment, while stepping up our efforts to manage chemical substances contained in our products.

- ★REACH Regulation: A chemical substance regulation in the EU on the “Registration, Evaluation, Authorization and Restriction of Chemicals.” Registration is required when exporting a chemical substance into EU states in quantities of one metric ton or more per year. Notification must also be submitted to the authorities when a chemical substance falling under the category of “candidate for required authorization” is present in a product at more than 0.1 percent of the mass of the object.

Product Information Flow

Chemical Leak Drills

The LINTEC Group conducts chemical spill drills at plants and research centers that handle chemical substances. The drills aim to enable employees to safely take steps in the event of a chemical spill to prevent possible secondary disasters, such as a spill extending to outside the premises, soil contamination, and fire. In fiscal 2022, drills were carried out at nine business sites, excluding the Head Office, which does not handle organic solvents defined by the Industrial Safety and Health Act. The number of participants totaled 541. A drill for a leak of LNG (liquefied natural gas) or city gas was also conducted, in which 75 employees participated.

- Message from the President

- Concept and Systems

- Highlight: Initiatives for the Reduction of CO2 Emissions

- Environmental Report

- Environmental Management System

- Developing Environmentally Friendly Products

- Climate Change Mitigation and Adaptation

- Realization of a Recycling-oriented Society

- Co-existence with Nature

- Management of Environmentally Hazardous Substances

- Environmental Accounting

- Environmental Data of Group Companies Outside Japan

- Relationship between LINTEC and the Environment

- Social Report

- Providing Value to Customers

- Cooperating with Suppliers

- Together with Employees (Human Rights / Employment)

- Together with Employees (Human Resource Development)

- Together with Employees (Safety and Disaster Prevention)

- Together with Local Communities

- Together with Shareholders

- Communicating with Stakeholders

- Governance Report

- SDGs-related Initiatives

- CSR Activities at Group Companies Inside and Outside of Japan

- Information Disclosure Based on TCFD Recommendations

- Corporate Policies

- Reporting Policy

- Performance Data

- GRI Index

- Message from Outside Director

- Third-Party Verification

- External Evaluations

- Download Report